Cold spray fundamentals

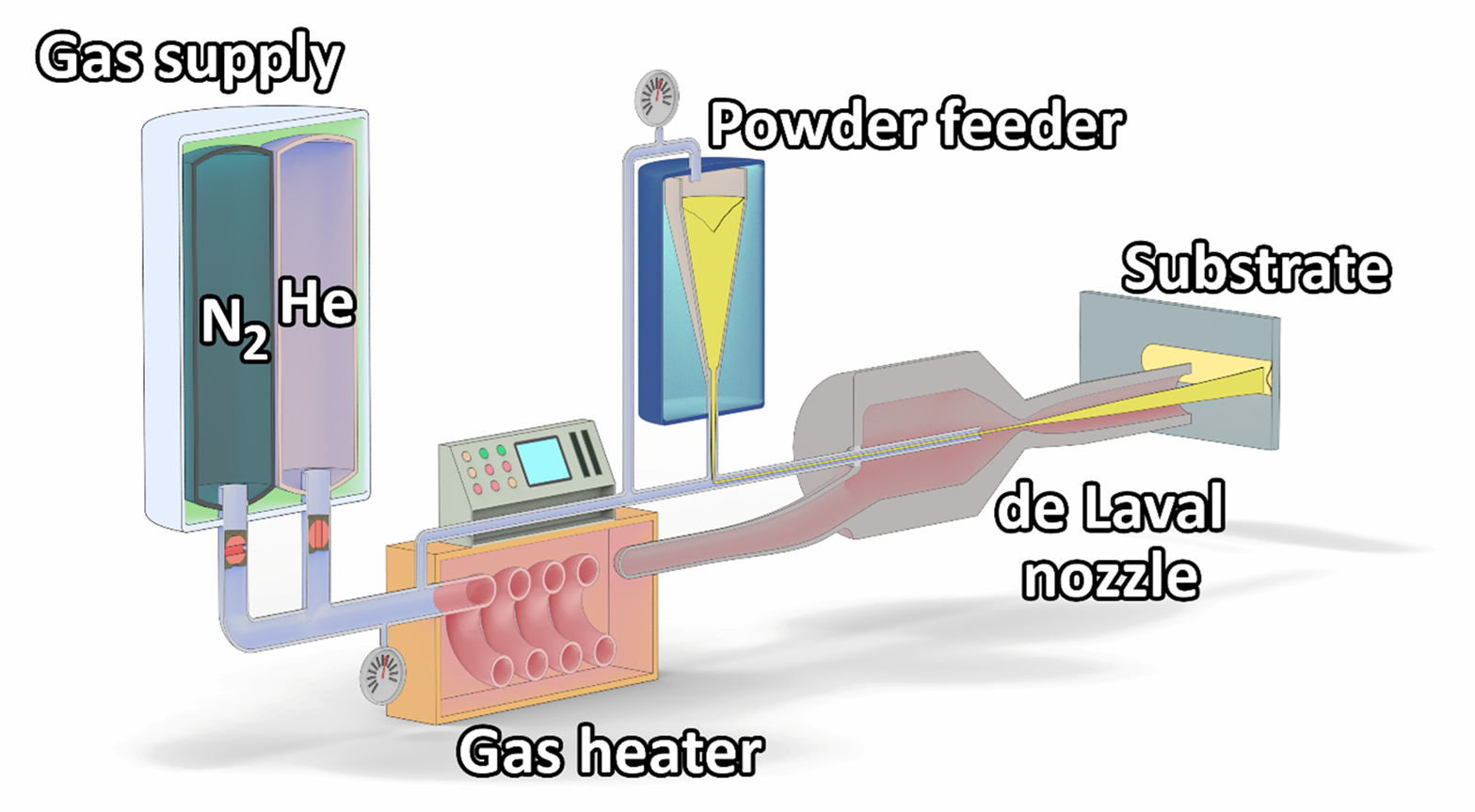

Cold spray is a cutting-edge technology for surface coatings, component repair, and additive manufacturing, particularly suited for metallic materials. Using a stream of compressed gases like nitrogen or helium it propels input powder particles at supersonic speeds onto a substrate to create uniform, dense, strongly bonded deposits without melting the material. This solid-state process minimizes all thermal effects and suppresses undesired phenomena typically occurring in thermal spray or laser-based additive manufacturing processes.

Owing to its advantages, cold spray technology is rapidly being embraced across industries such as aerospace, automotive, defense, energy, marine, and medical. Its versatility allows e.g. applying wear-resistant, corrosion-resistant, and functional coatings; repairing worn or damaged components to extend their service life; and additive manufacturing to build or redesign complex parts layer-by-layer.

Applications

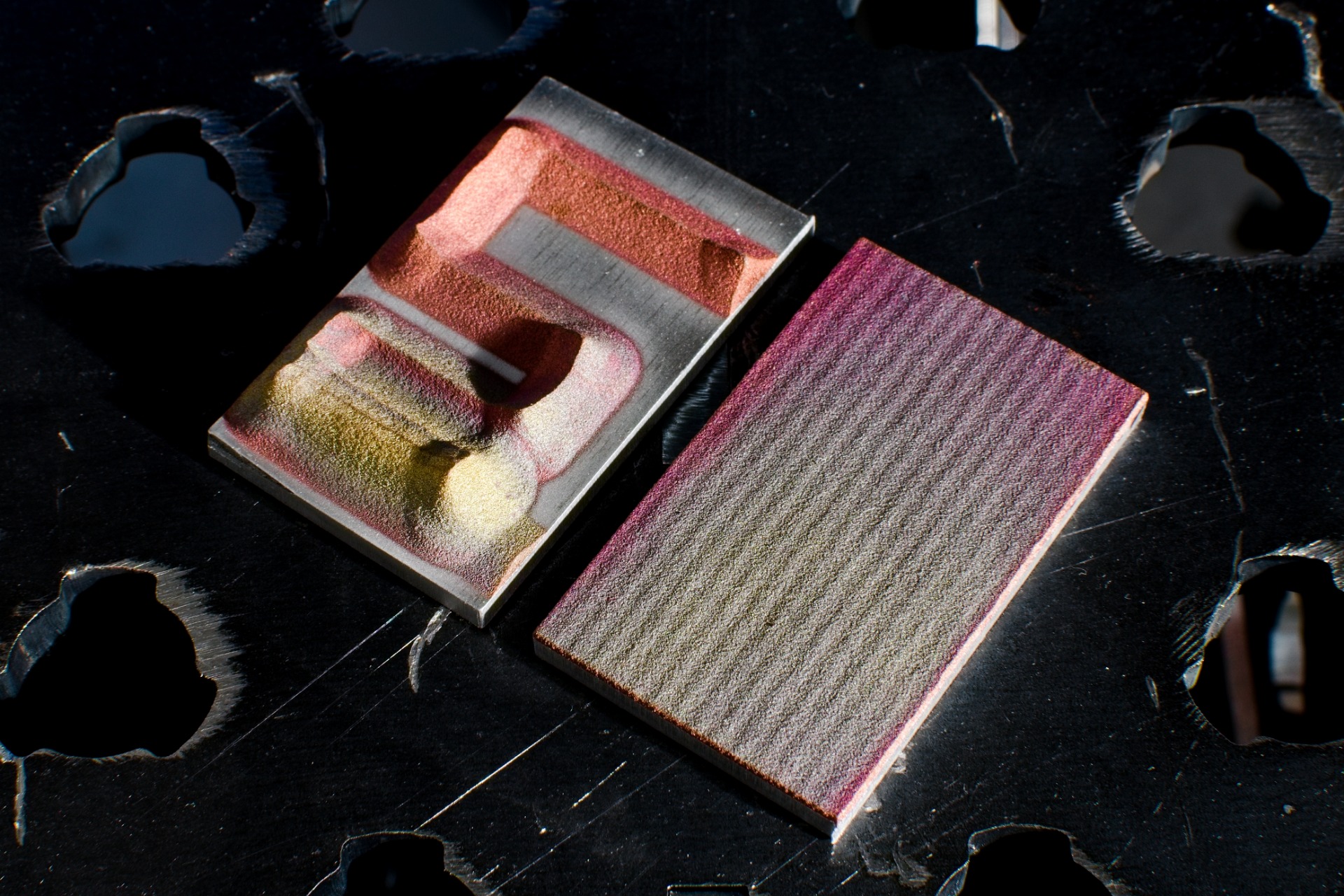

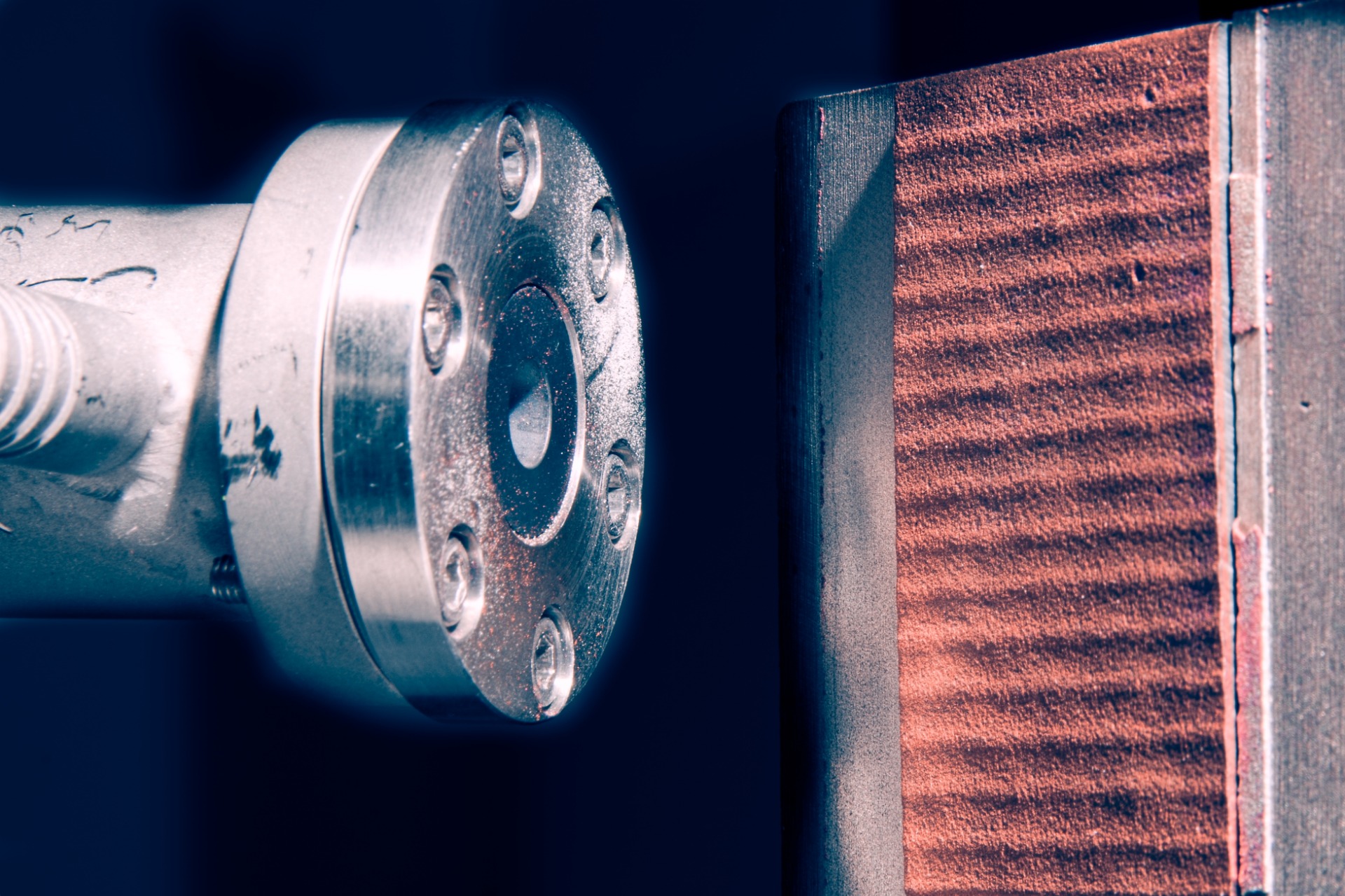

Thick protective or functional surface coatings

Repair and dimensional restoration of damaged components

Additive manufacturing without dimensional constraints

Main benefits

- solid-state deposition without melting or significant heat input

- deposits of high density, hardness, strong mechanical bonding and compressive residual stresses enhancing lifetime and durability

- versatility in processed materials including metals, alloys, and composites

- very high process efficiency and high productivity with rapid deposition rates, order of magnitude higher than laser-based additive methods

- no component thermal distortion, ability to coat temperature-sensitive materials such as titanium, copper, polymers, and composites

- minimal surface preparation required, perfect machinability of the deposits

- no oxidation, chemical or phase changes of the materials, negligible porosity

- environmentally friendly, no combustion or toxic waste

- no problems with reflective metals or blends with different melting temperatures